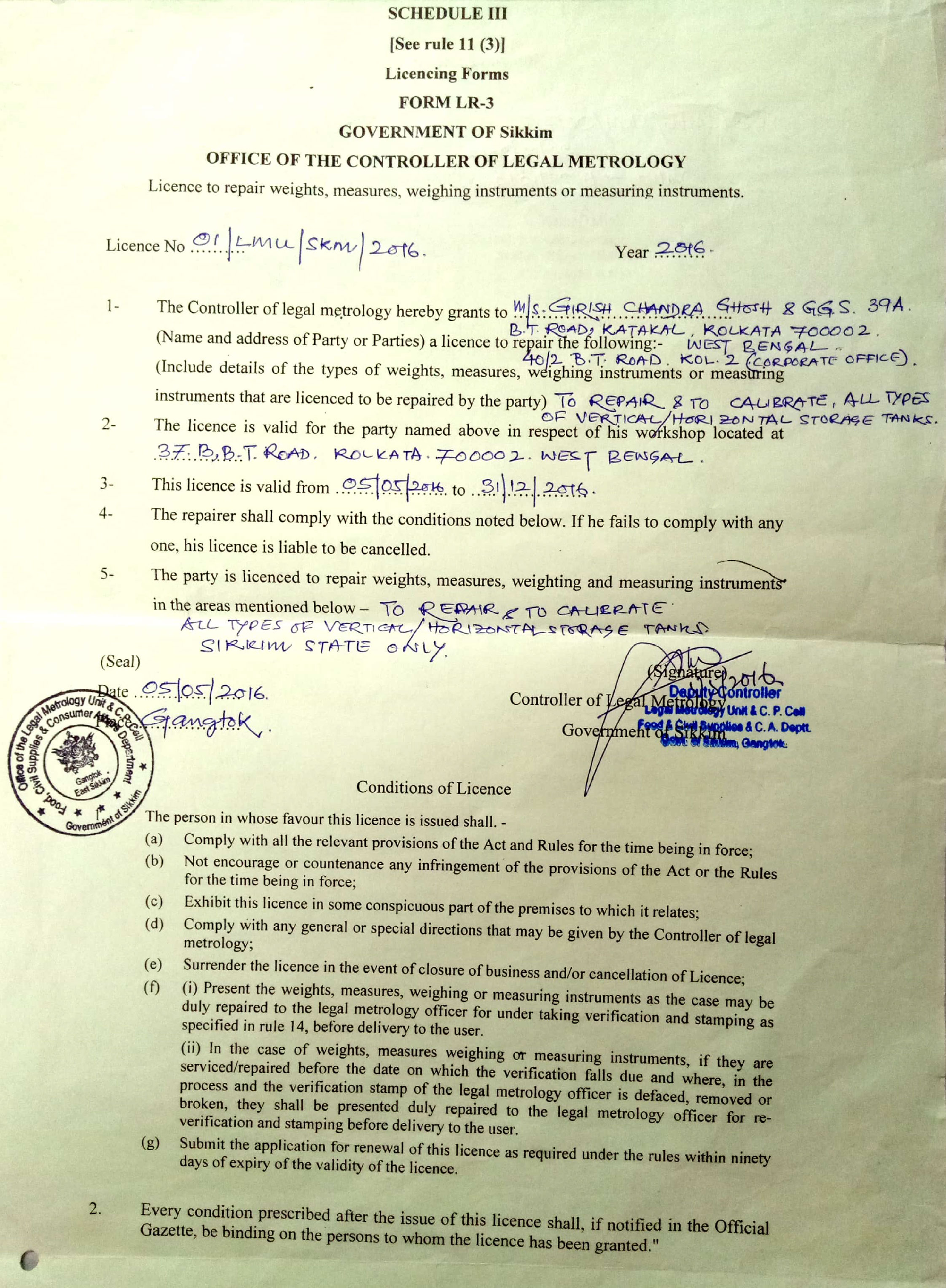

- Upright Cylindrical Tank Calibration: Manual Strapping. (API 2550/ ISO 7507-1:2003.

- Optical Reference Line Method (ISO 7507-2:2005).

- OTM, Optical Triangulation method (ISO 7507 -3:2006).

- EODR, Internal Electro-Optical distance ranging method (Laser) (ISO 7507-4:2010)

- EODR, External electro-optical distance-ranging method (Laser) (ISO 7507-5:2010)

- Calibration of Horizontal Tanks. (API 2551)

- Calibration of Spherical Tanks. (API 2552)

Petroleum and liquid petroleum products -- Calibration of vertical cylindrical tanks -- Part 1: Strapping method

Petroleum and liquid petroleum products -- Calibration of vertical cylindrical tanks -- Part 2: Optical-reference-line method

Petroleum and liquid petroleum products ---- Calibration of vertical cylindrical tanks -- Part 3: Optical-traingulation method

Petroleum and liquid petroleum products -- Calibration of vertical cylindrical tanks -- Part 4: Internal electro-optical distance ranging method

Petroleum and liquid petroleum products -- Calibration of vertical cylindrical tanks -- Part 5: External electro-optical distance ranging method

As in the ORLM, the number of horizontal stations should be selected according to tank diameter. The minimum number of stations as shown in the table should be used, but the number of maximum stations is left to the choice of the person doing the work. Obviously, the more stations used the better accuracy of the calibration.

For Vertical Storage Tank

2007-1974 : Method for Calibration of Vertical oil storage tanksFor Horizontal Storage Tank

2009-1975 : Method for Calibration Horizontal and tilted oil storage tanksSTATUTORY OBLIGATION FOR CALIBRATION

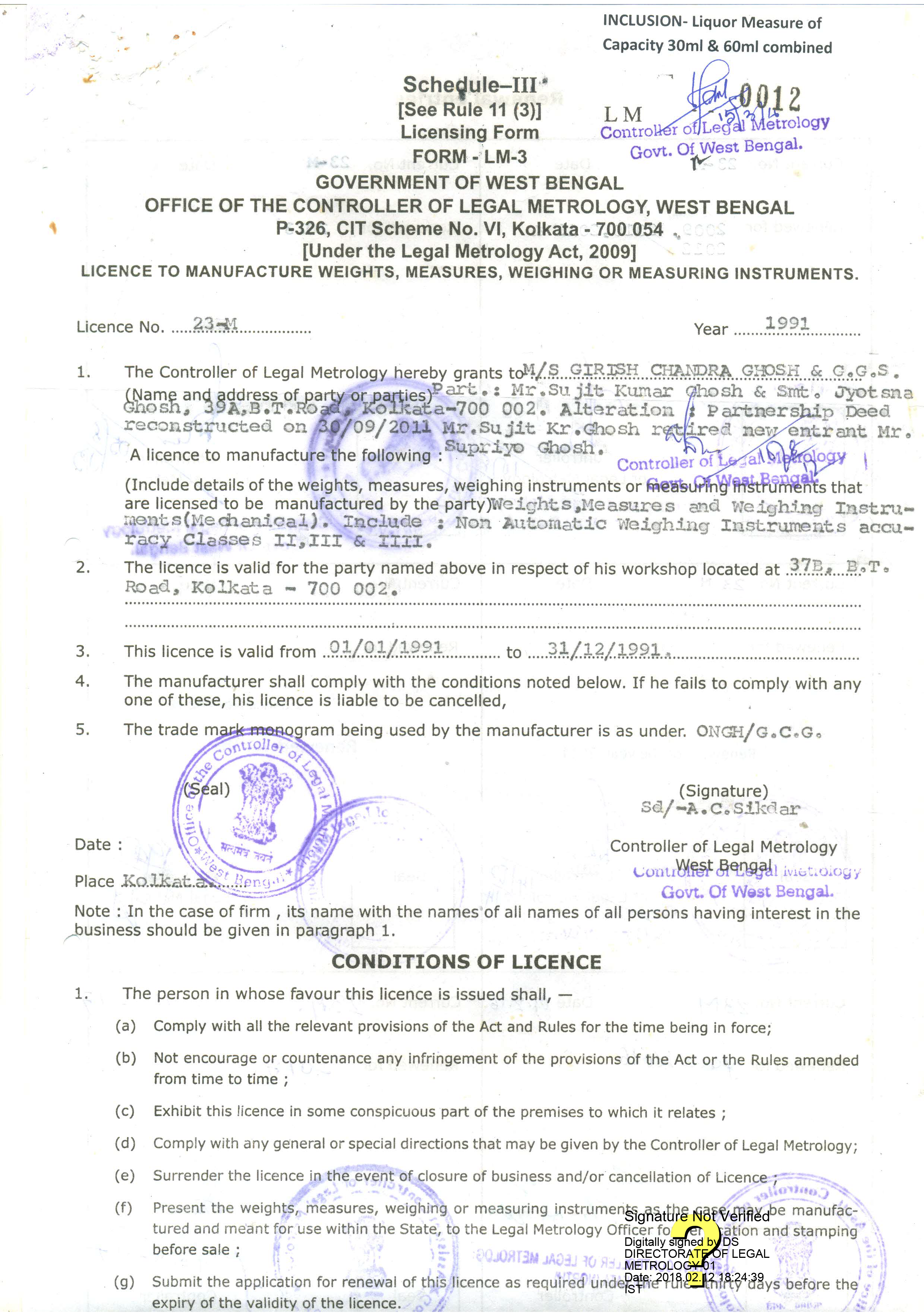

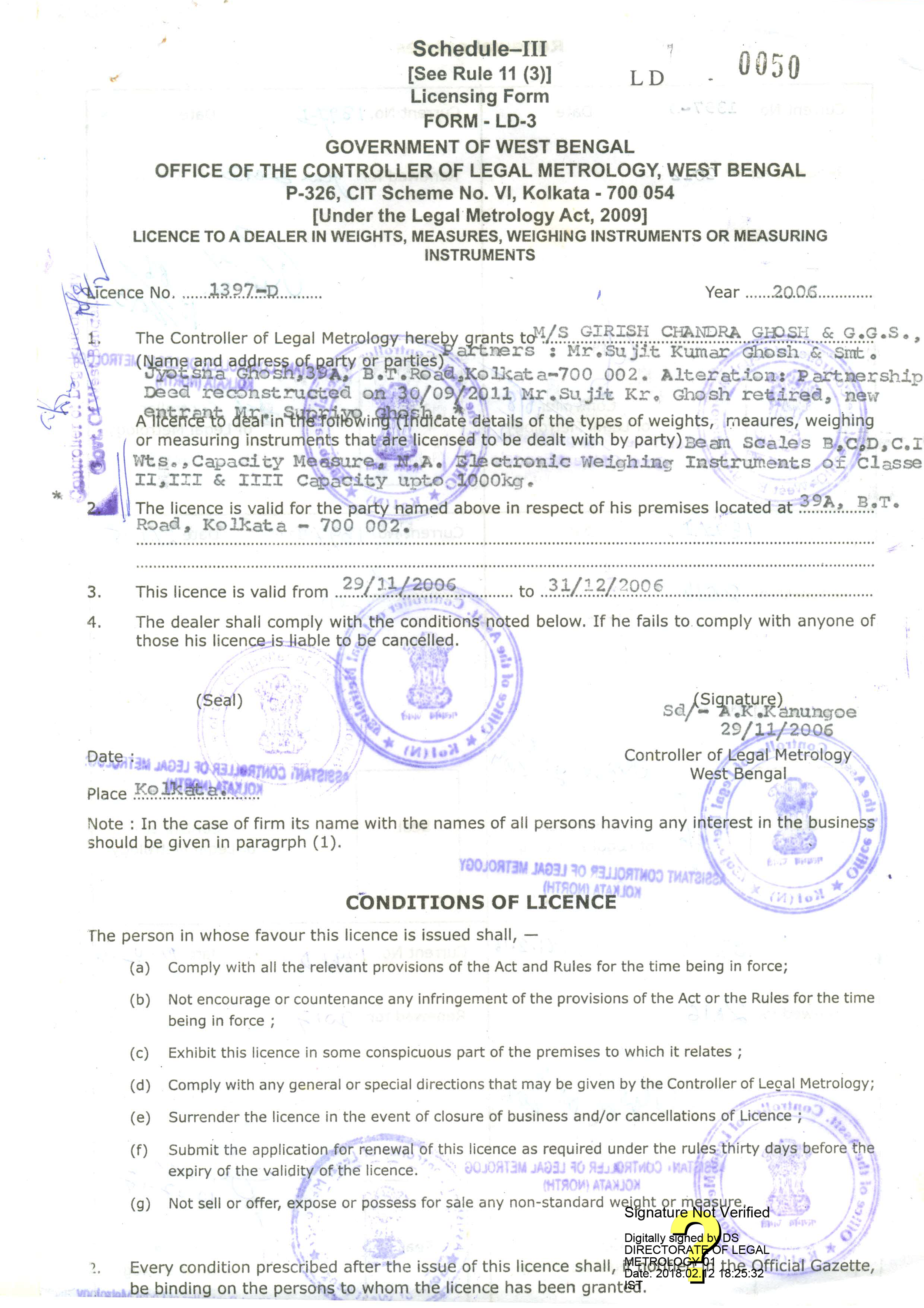

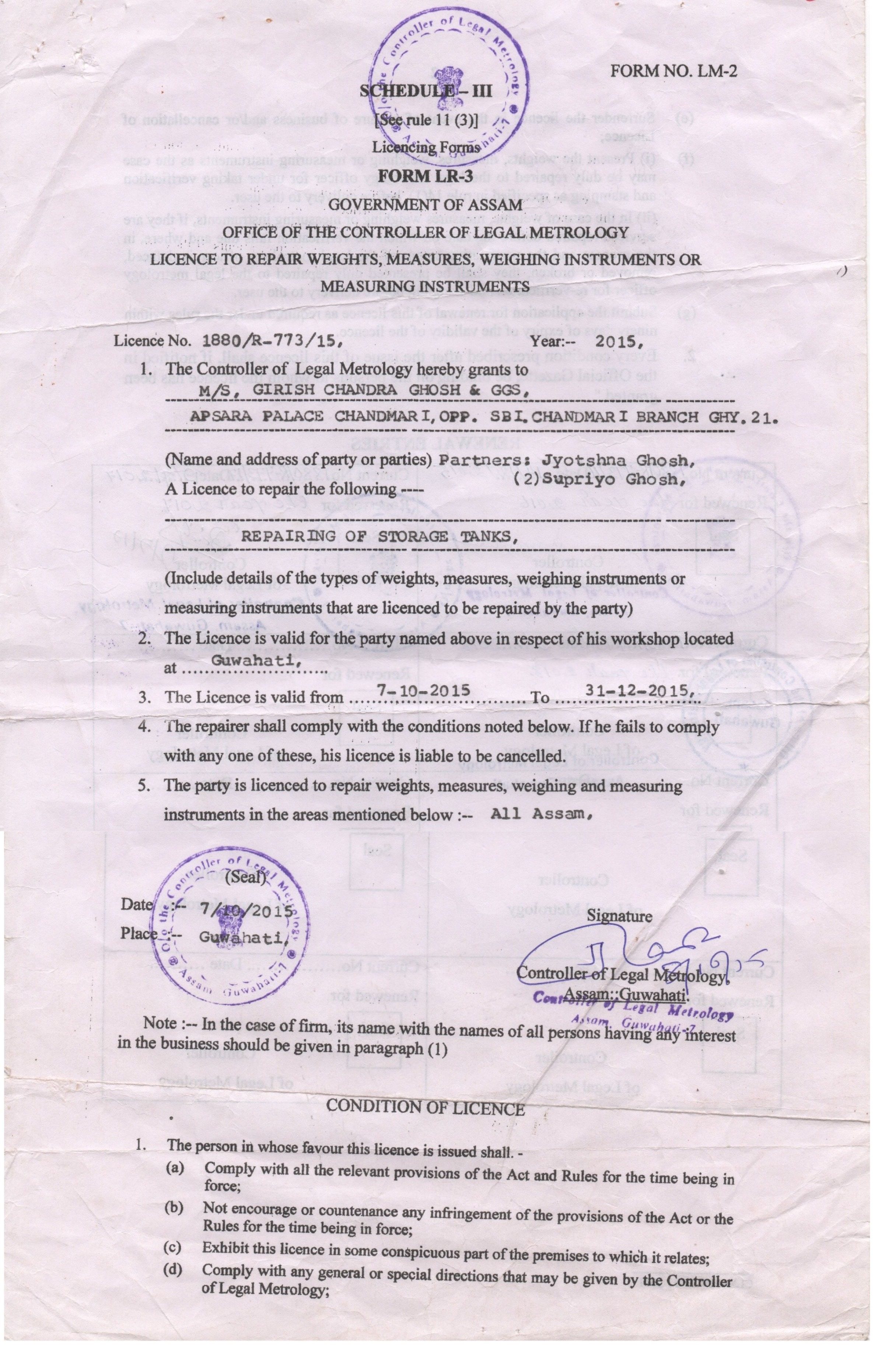

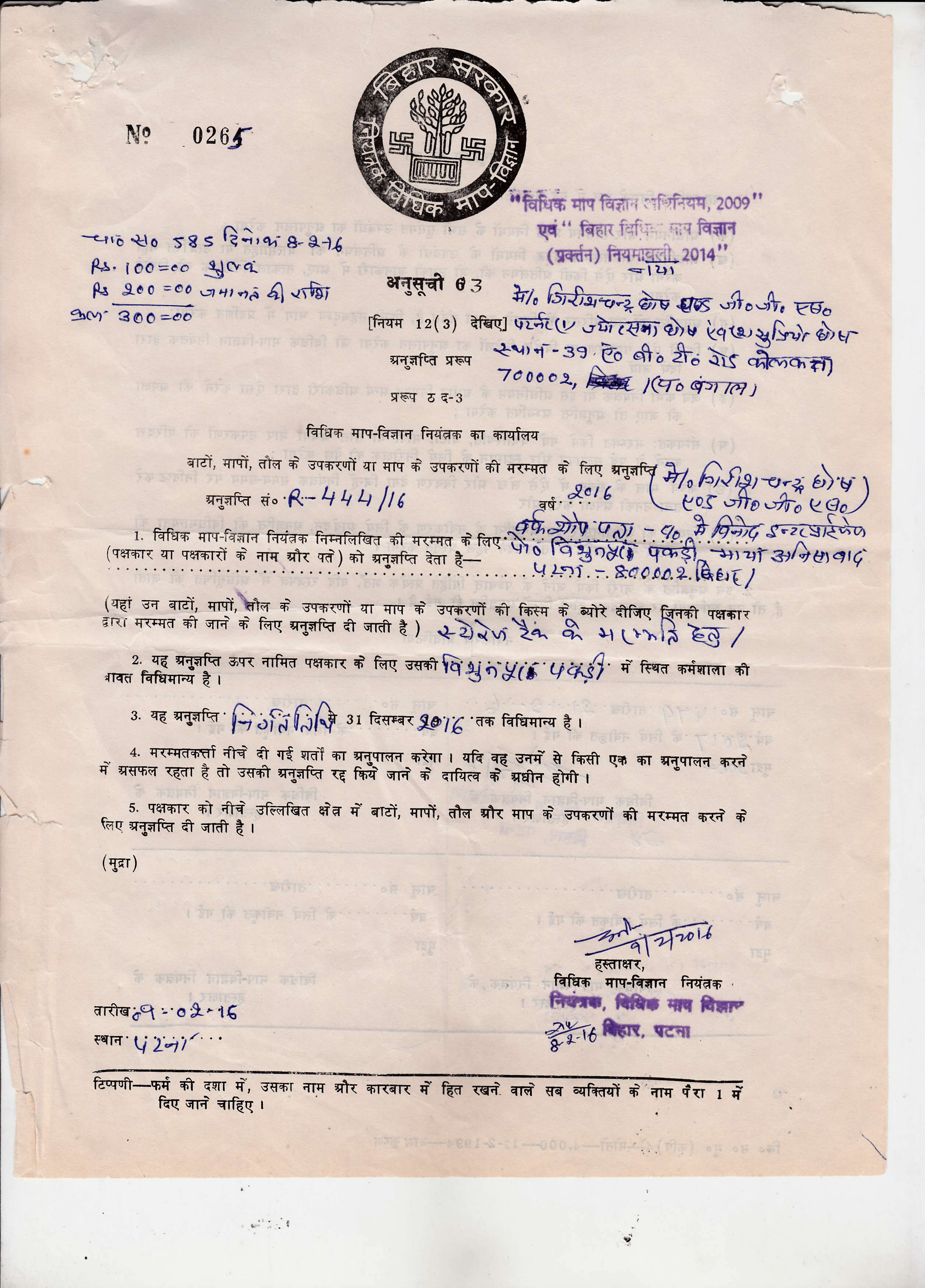

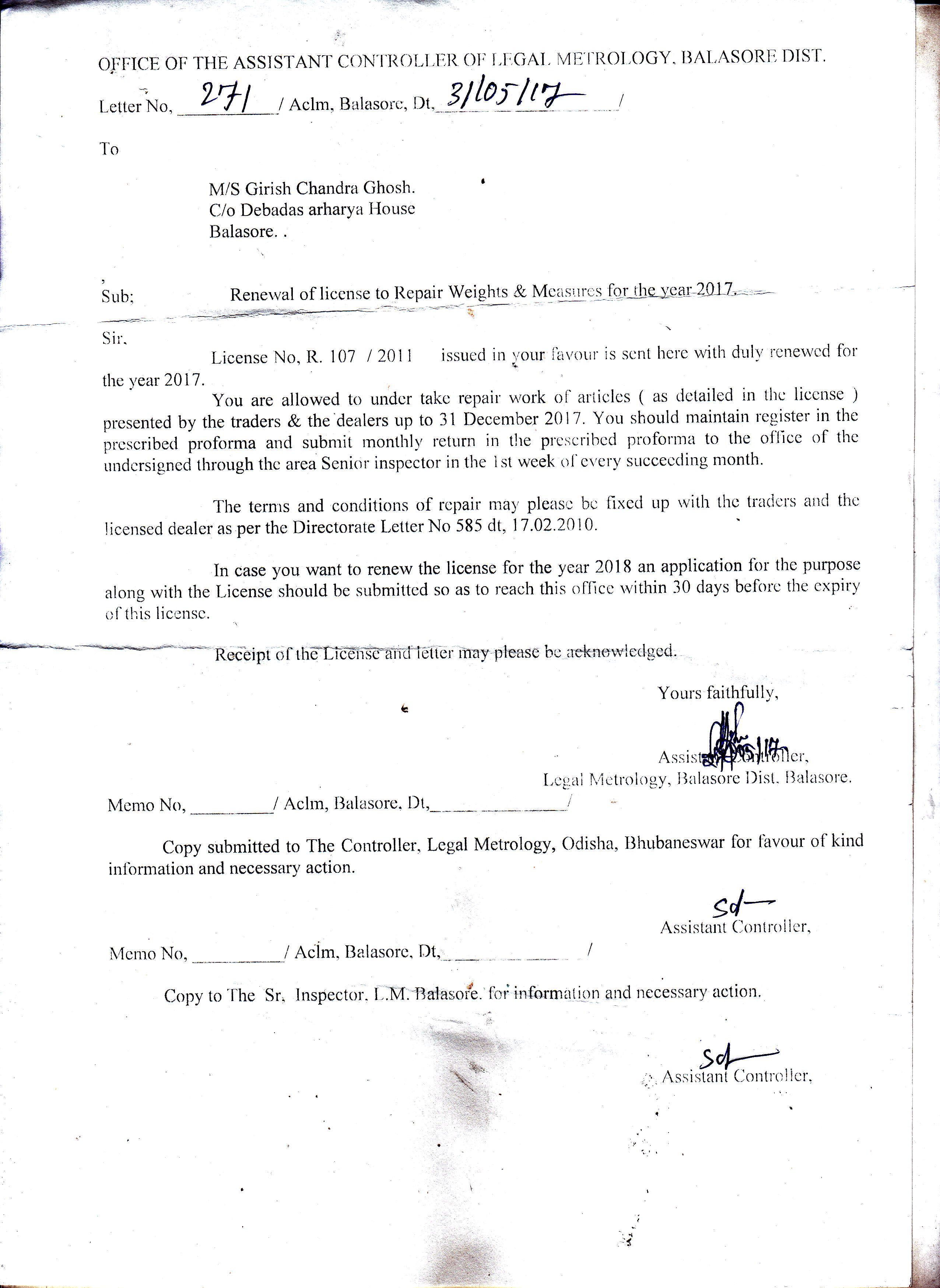

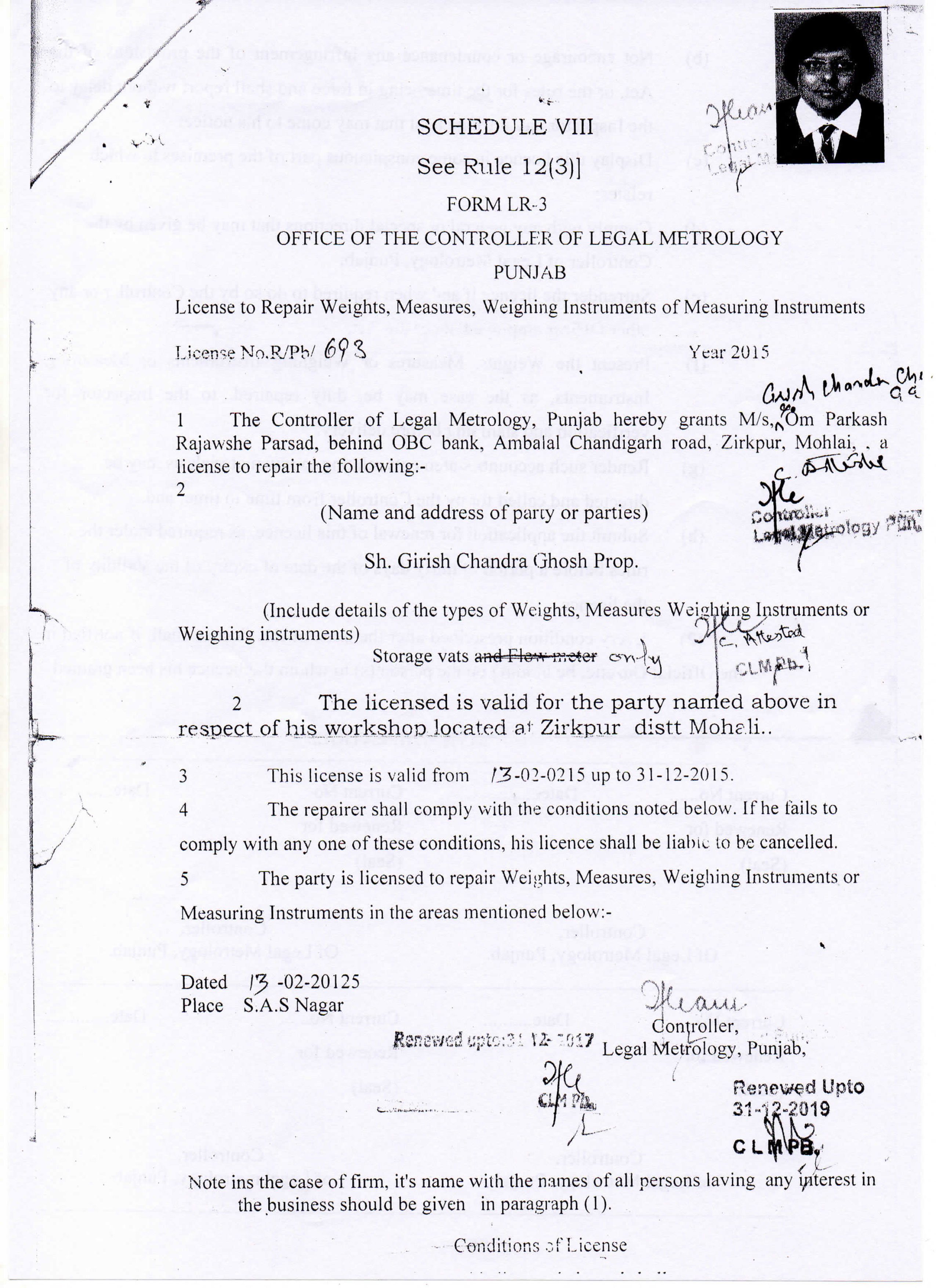

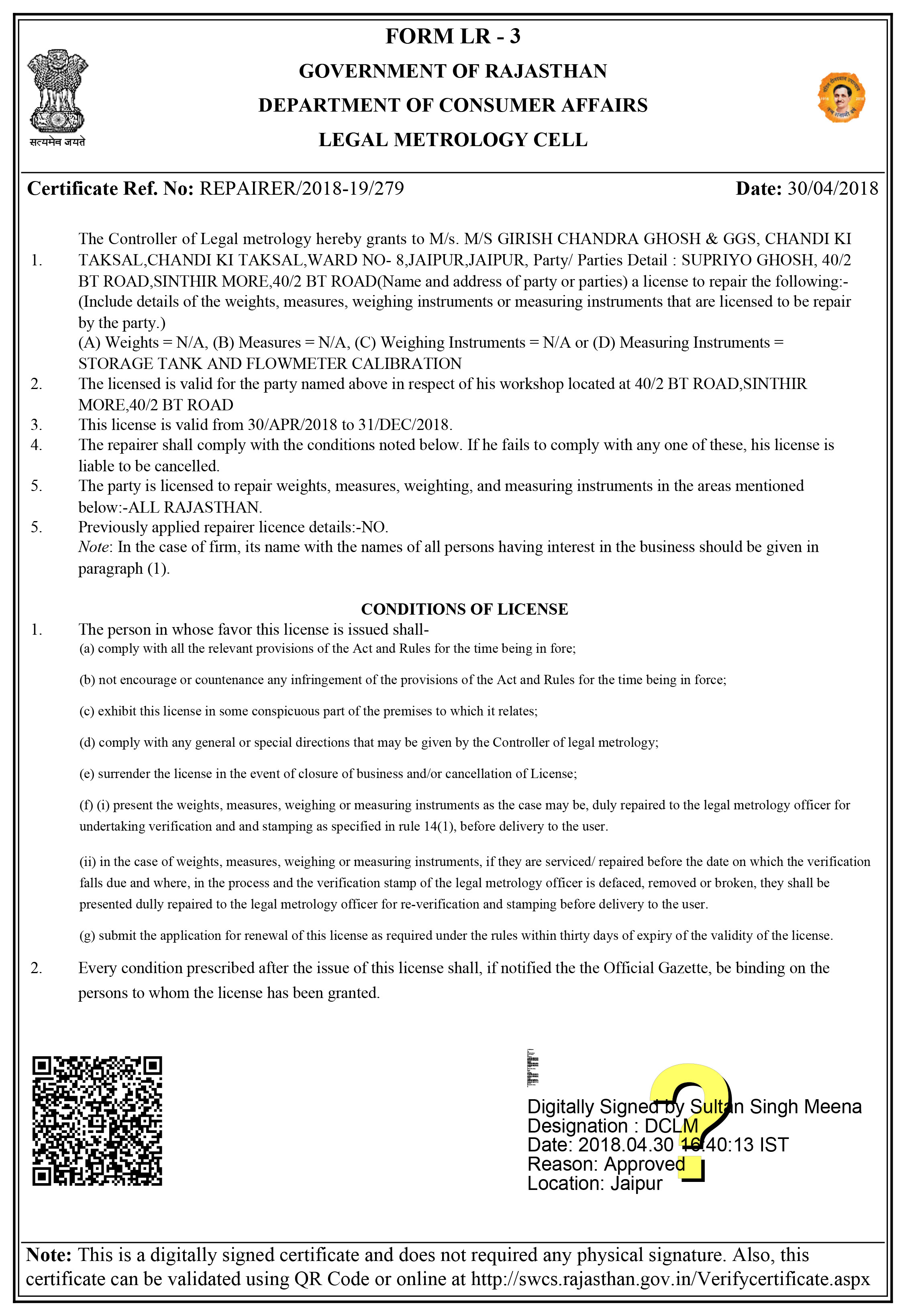

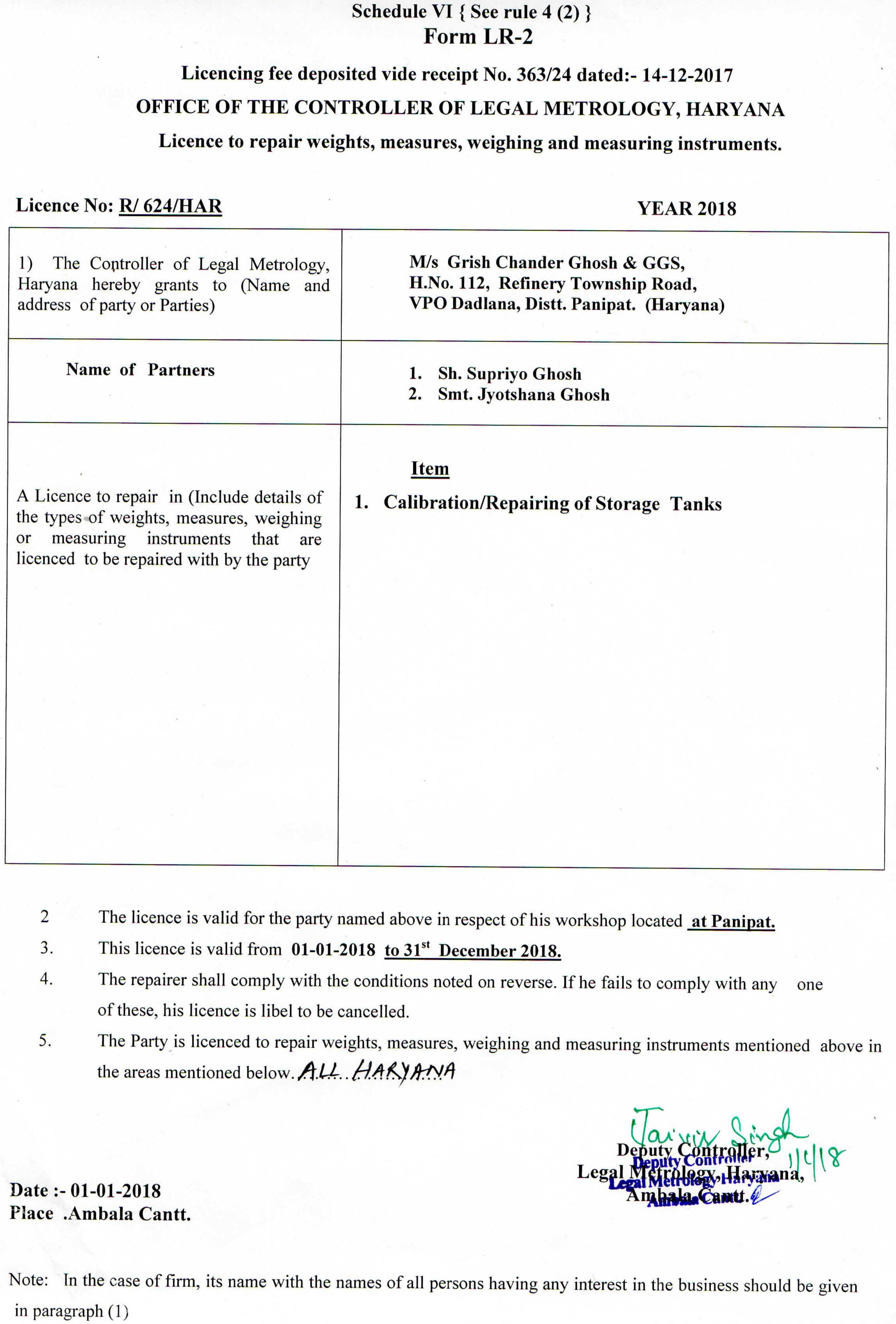

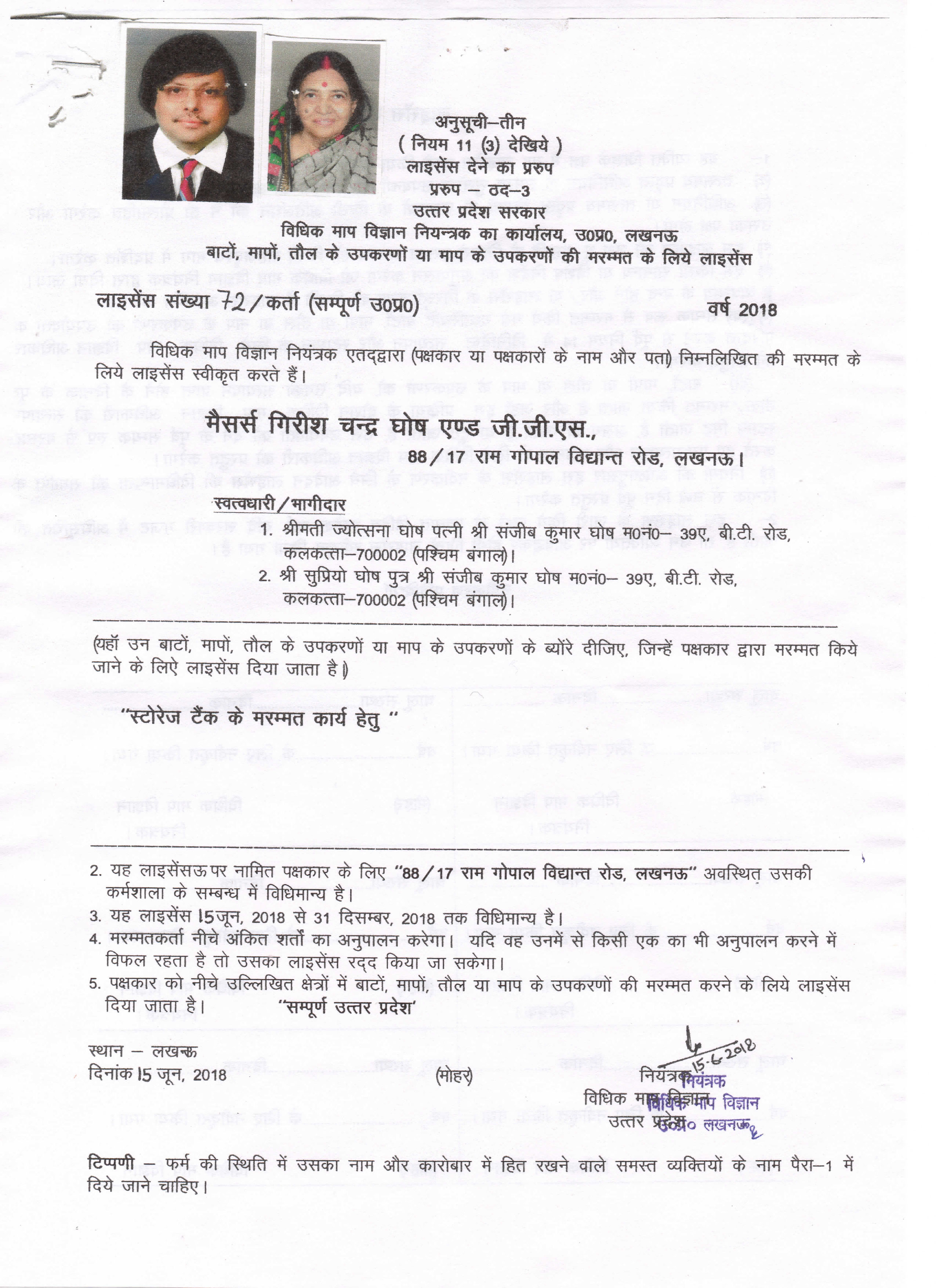

2009-1975 : As per the provision of section 27of the standard weights and < General > measure rule 2011 no weights and measure shall be sold or offered possessed for sale use of kept for use in any transaction or protection unless it has been verified & stamp and as provided in State Enforcement Rule 2011 framed under the Legal Metrology act 2009. The storage tank including vats used or intended to be used in any Transaction or tor protection must be revivified or recalibrated and stamp at least once in 5 years the definition of the word the Transaction defined in 2 < u > of the standard Legal Metrology act 2009 under which the said act has been enacted which runs as follows :-(i) any contract for Sale, Purchase, Exchange or any other purpose.

(ii) any assessment of Royalty, Toll or other dues.

(iii) any assessment of work done, wages dues or service rendered, their Storage tank can't be excluded from the purview of the above said Act & Rules.

For ISO quality certification of Calibration of Storage Tank is essential accurately required by ISO official

• To meet Central Excise / State Excise & custom Duty obligation in view of the aforesaid - it is essential to get storage tank calibrated by owners and to get rid of any legal action

as provided in the said Act.

• Fines & seizures for noncompliance.